Electronic semiconductor

Project overview

The chemicals used in semiconductors require very high purity and have special requirements for the equipment structure. The mixture can meet the requirements of mass and heat transfer, reaction crystallization, dispersion and emulsification, and can be customized according to the process requirements.

Description of materials and working conditions

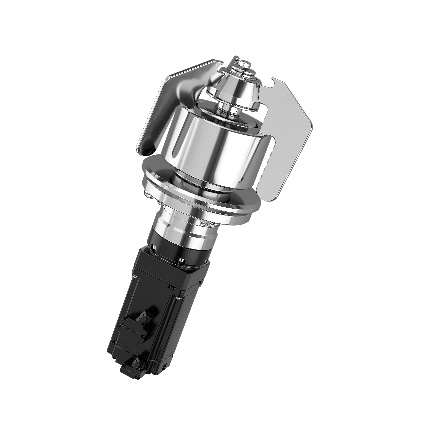

Take photoresist as an example, the continuous phase and dispersion in the tank need to be mixed at a certain flow rate. Usually, in the early stage of equipment selection, we will build a stirring model, match the fluid parameters for CFD fluid simulation, and then optimize according to the calculation results. Magnetic stirring can be used for mixing, which can completely avoid contamination of materials in the tank.

High viscosity conditions can be selected with mechanical seal mixing, mechanical seal structure needs special design to prevent contamination of materials.

Material system composition

Operating temperature

Use effect description